Design Process

I often get the question, “How long did that take to make?” in regard to woven items. I confess I haven’t kept very good records in the past. There are nine major parts of the process: Designing, Measuring, Warping, Threading, Sleying, Winding, Tieing, Weaving, and Finishing. The actual act of sitting at the loom, throwing the shuttle, and beating the fell — the actual making of the cloth — is often the shortest part.

My design process looks a lot like this:

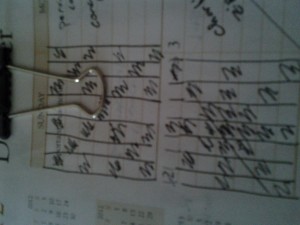

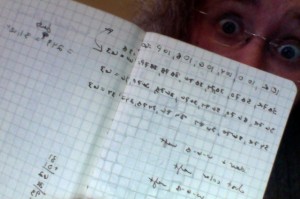

Some of the calculations you need to make:

Yarn grist (how fat is your yarn)

Finished cloth sett (how dense do you want your cloth to be?)

Warp length (loom waste + sampling + finished project)

Warp width / cloth density = ends per inch (how many warp threads do you need?)

Weft length (warp width + 10% x number of weft picks per inch x number of inches in total project and samples)

With all the thinking and math figured out, it’s time to wind the warp!