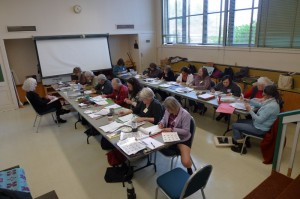

Complex Weaver’s Guild Fine Threads Study Group 2012

Fine Threads Study Group 2012 Weaving Notes Jen Garrison Stuber

Pre-weaving notes:

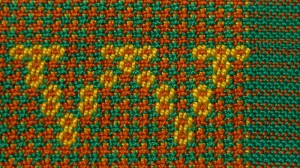

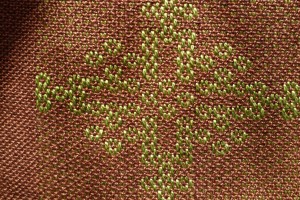

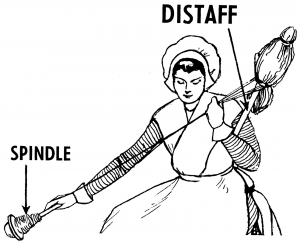

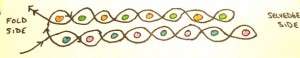

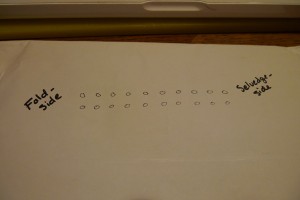

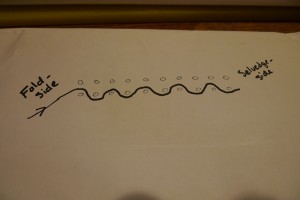

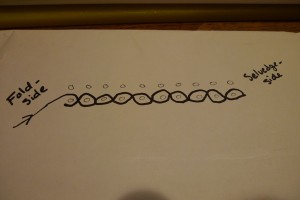

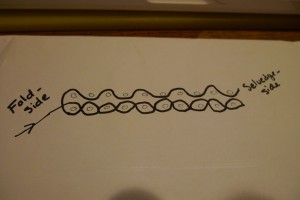

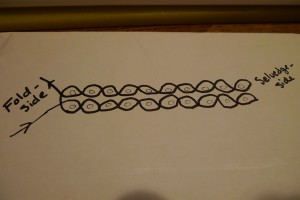

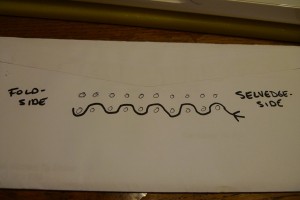

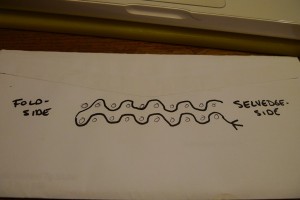

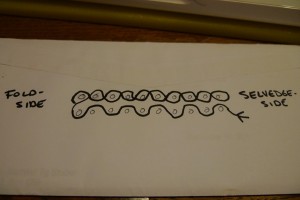

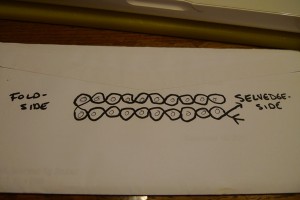

I was inspired to join the Complex Weavers (and then the Fine Threads Study group) by Lillian Whipple’s article on WeaveZine, about weaving letters. The definition for the Fine Threads Study group is a thread that is “fine for you.” 10/2 is the finest thread I’ve worked with to date, this is my first run at it. Earlier this year, I went to Portland for a block workshop with Rosalie Neilsen, and started working with Summer and Winter when I got home, using a 5/2 UKI cotton for the background, and a 3/2 cotton for the pattern. This is my first project on my shiny new 12 shaft Spring, though I have worked on an 8 shaft Spring in the past. I wanted to use the 12 shaft so that I could produce 9-block letters (leaving shafts 1 & 2 for tie-down, and shaft 3 for a border).

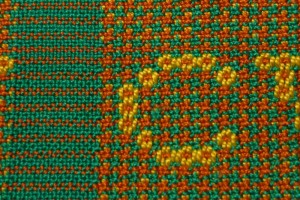

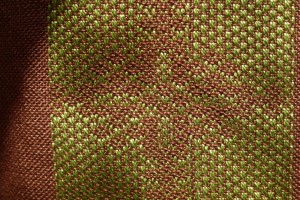

Further, I decided to increase the complexity of my weaving by making the background a houndstooth in complementary colours, which I hope will be wildly live, but not vomit-inducing. It took a long time to decide on a block colour (I started with a brown, which ended up looking sadly matte, and also discarded a magenta and a wild teal). I’m not sure the houndstooth won’t get lost with the dots of the pattern thread running through it, and I hope I don’t hate myself for picking something that takes three shuttles. I also hope that I am a capable-enough weaver to make relatively decent selvedges.

Weaving Post-mortem:

The first major mistake I made was in not winding enough warp. Although I had figured the main project would only take a little more than a yard, and I therefore added two additional yards for loom waste and sampling, I did not calculate a number of mistakes, which included a miscalculation of how long “CWG” would be, a clerical error that resulted in making two sets of “cW” instead of “CW”, and the final undetected threading error that I wove all the way through. I was able to make 7 sets before I ran out of warp, thus allowing me to send the more perfect examples to the study group. I keep meaning to adopt the maxim, attributed to any number of religious fiber artists across the world (including Muslim weavers and Amish quilters) that “only God is perfect,” and therefore the errors are intentional– but that is not the case here.

The second mistake I made was using a countermarch loom with a skeleton tie-up that did not (and in several cases, because of triple-treadling, could not) account for all the shafts. In the sampling phase, I attempted to remedy this by use of make-shift sword like Thai backstrap weavers use (though in my case, I used a long stick shuttle), but I still caught a number of warp threads. In the weaving, I decided that lifting (or pushing) shafts into place while weaving was faster and more accurate.

But in addition to being annoying and slow, I think several of my errors were still the result of not having a clean shed. In retrospect, I should have tied up the upper-lamms on all the shafts except 1-2 for all the single-use treadles, and figured out some way to tie up as many as I could on the double-use-treadles. I did find Tim’s Rudimentary Treadle Reducer ( http://www.cs.earlham.edu/~timm/treadle/form1.php ), which was a great help with the original tie-up for “CWG” and unnecessary for the final “CW” variation, as I had enough treadles without reducing.

I am getting better at discovering mis-treadling as I weave, and I ended up doing a lot of un-weaving as I went, but generally not more than 6 picks (the scissors and I have become good friends). I have also concluded that weaving software, and not graph paper, is the way to go to document drafts. (Though I confess that drinking a beer while trying to draft with permanent ink pens is not the brightest idea).

All in all, I am pretty happy with the results, though, as I am about to commence cutting my cloth in preparation of sending it, I hold a bit of terror at that prospect. I plan to iron on an interfacing to prevent unraveling, and mount the samples with archival tape. Then, I plan to have a beer.