Figure My Figure

I went to the Figure my Figure meeting for the Guild’s 2016 Yardage Challenge — how to figure out how much you need to weave for the pattern you’ve chosen. These are my notes.

First, you’ve got to pick a pattern. The upside to a pattern like this one is that it has many pieces — many pieces tends to mean that each piece is not super-wide, and that means that you can weave your cloth on a smaller (narrower) loom. Most patterns have the yardage labeled for 45″ or 60″ cloth — and if your loom’s that wide, bully for you, but if it’s not . . . well . . .

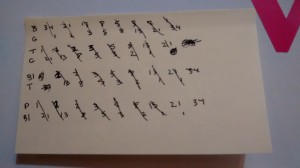

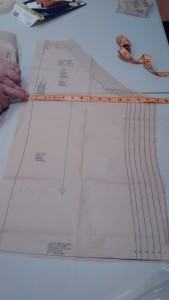

Next up, take all the pieces out. What you’re looking for is to find the largest one that is the widest across:

Next up, take all the pieces out. What you’re looking for is to find the largest one that is the widest across:

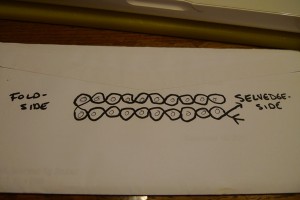

Measure it at the widest point. This, plus the selvage, plus shrinkage, is your minimum width.

Measure it at the widest point. This, plus the selvage, plus shrinkage, is your minimum width.

Our intrepid weaver’s guild president, Sarah Laudenbach, a long time seamstress, suggests tracing all your pattern pieces on to tracing paper, and using the tracing paper pattern for your garment, keeping the original for reuse. If you use (or cut down your) tracing paper to the maximum width of your cloth on the loom (minus the selvage, minus shrinkage), you can’t go too wrong.

Our intrepid weaver’s guild president, Sarah Laudenbach, a long time seamstress, suggests tracing all your pattern pieces on to tracing paper, and using the tracing paper pattern for your garment, keeping the original for reuse. If you use (or cut down your) tracing paper to the maximum width of your cloth on the loom (minus the selvage, minus shrinkage), you can’t go too wrong.

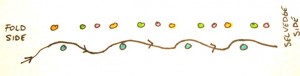

Remember, you have to line up the pieces with the grain. Check the arrows, and get everything going in the right direction. When you get everything traced, and before you start cutting the tracing paper, measure the length of the tracing paper. This, plus shrinkage, is the minimum length you need to weave for your pattern. Weave more.

Remember, you have to line up the pieces with the grain. Check the arrows, and get everything going in the right direction. When you get everything traced, and before you start cutting the tracing paper, measure the length of the tracing paper. This, plus shrinkage, is the minimum length you need to weave for your pattern. Weave more.

A trick for lining up the pattern with the cloth: measure from the grain line to the edge of the cloth in several places, so you know that you’re straight with the grain of the cloth.

A trick for lining up the pattern with the cloth: measure from the grain line to the edge of the cloth in several places, so you know that you’re straight with the grain of the cloth.

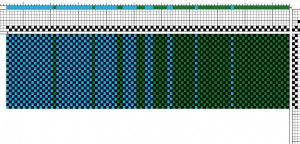

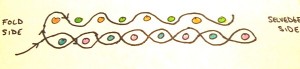

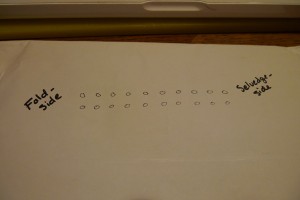

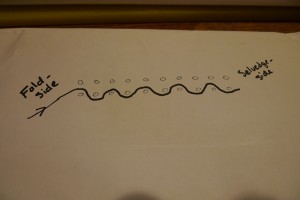

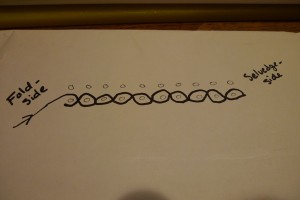

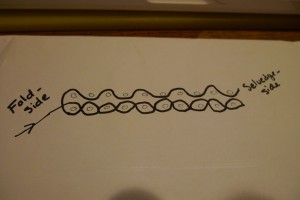

If you are using cloth with an obvious pattern/stripe/grid, you’re going to need more cloth, because you’re going to use the little dart-arrows in the pattern to line up with the lines in the cloth. You may need substantially more cloth to do this, if you have a long repeat.

If you are using cloth with an obvious pattern/stripe/grid, you’re going to need more cloth, because you’re going to use the little dart-arrows in the pattern to line up with the lines in the cloth. You may need substantially more cloth to do this, if you have a long repeat.

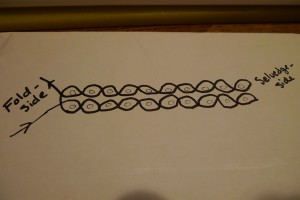

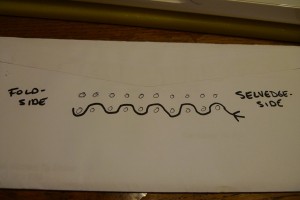

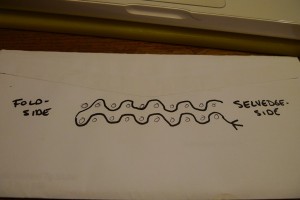

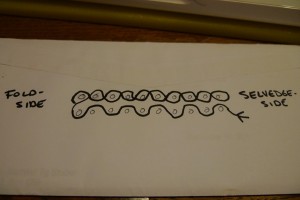

Before you cut your cloth, it’s a good idea to trace the pattern of the cloth onto your pattern piece, to make sure the cloth pattern falls in the right place.

Before you cut your cloth, it’s a good idea to trace the pattern of the cloth onto your pattern piece, to make sure the cloth pattern falls in the right place.

Sarah suggests drawing it in on the whole thing.

Sarah suggests drawing it in on the whole thing.

I don’t know about you, but I’m still not feeling super-sure about this whole thing . . . weaving yardage, no problem — cutting my cloth . . . . eek.